As industry leaders, we specialize in delivering cutting-edge solutions in Ultrasonic Testing (UT), with a particular focus on the advanced techniques of Phased Array UT and TFM / FMC. Our commitment to excellence extends to Visual Testing (VT), Magnetic Particle Testing (MT), and Penetrant Testing (PT), providing comprehensive NDT services tailored to your needs.

NDT Methods

-

![Ultrasonic Testing]()

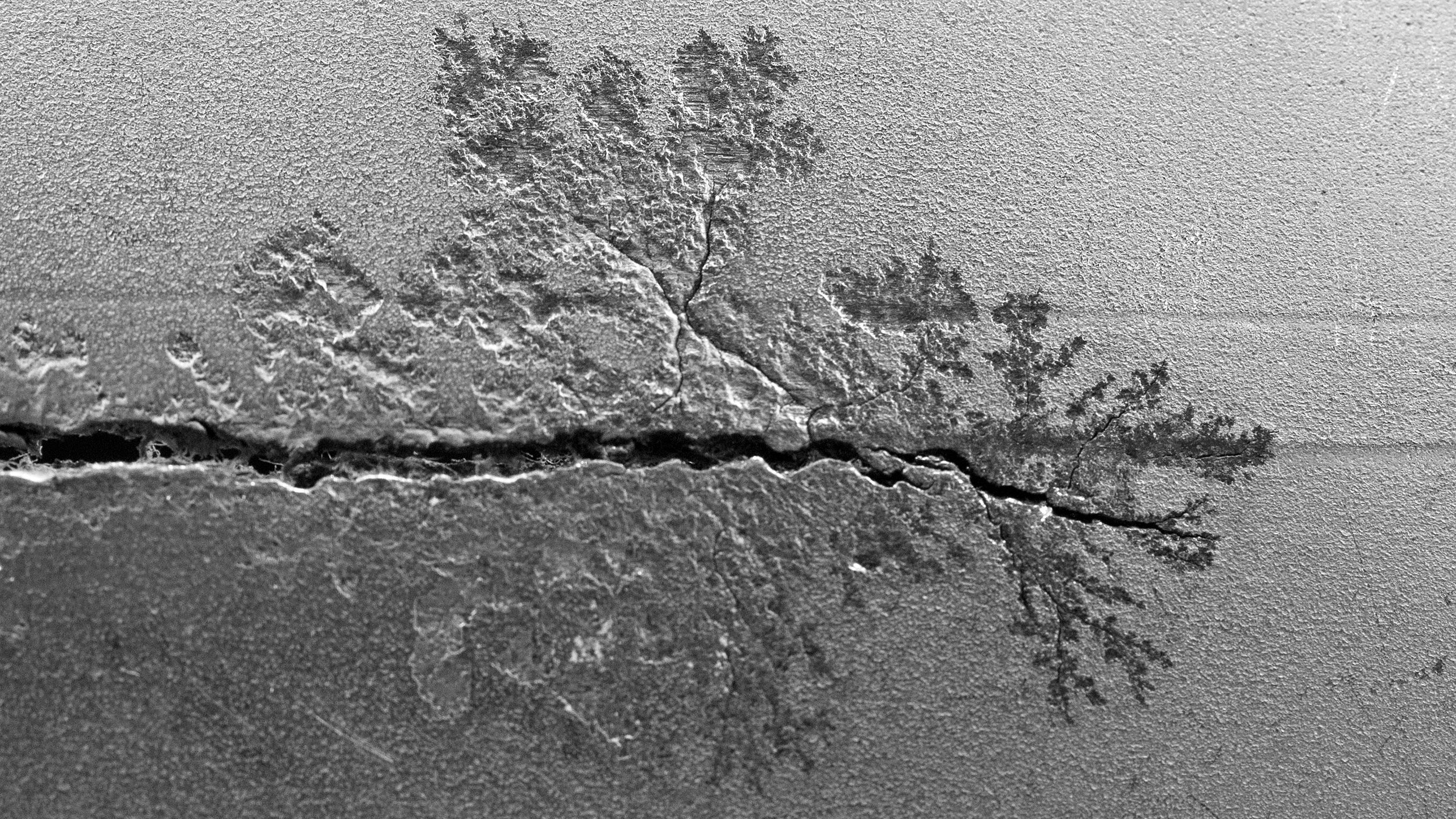

Ultrasonic Testing (UT)

Empowering Your UT Inspections:

At Rogue, we empower your Ultrasonic Testing (UT) inspections through a comprehensive suite of services.

How We Add Value:

Consulting Excellence:

Leverage our UT consulting services to optimize your inspection processes. Our experts provide insights tailored to your industry, ensuring effective and efficient inspections.

Customized Procedures:

Benefit from meticulously crafted UT procedures designed to meet the unique demands of your applications. Our procedures prioritize accuracy, reliability, and compliance.

Training for Excellence:

Elevate your team's skills with our UT training courses. From Level I to Level III certification, we impart practical knowledge and real-world insights for proficient UT inspections.

Innovative Solutions:

Rely on our innovative UT solutions, incorporating the latest technologies to enhance flaw detection, sizing, and characterization. We stay at the forefront of advancements to keep your inspections ahead of the curve.

-

![Phased Array Ultrasonic Testing (PAUT)]()

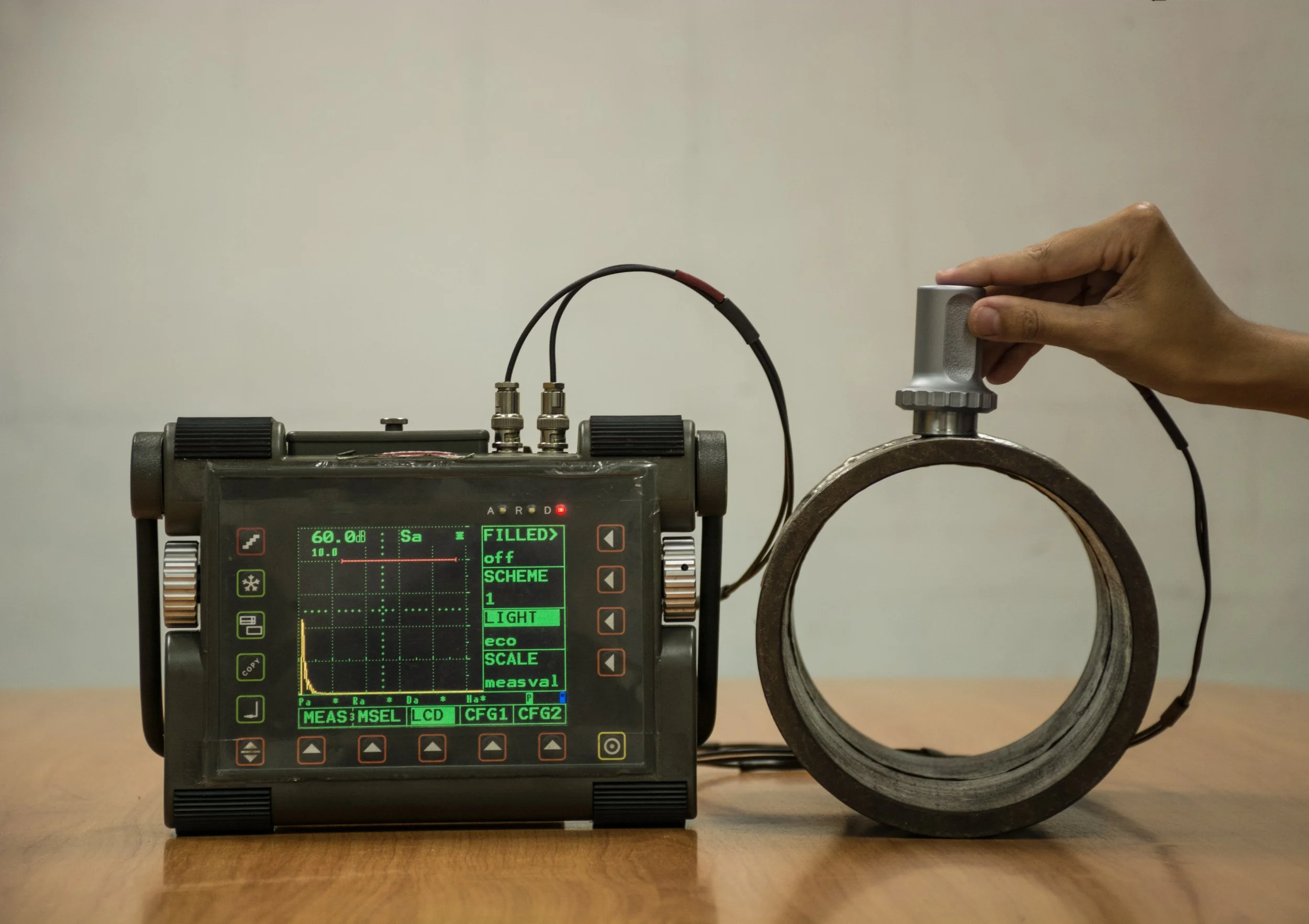

Phased Array Ultrasonic Testing (PAUT)

Advancing Your PA Inspections:

Explore the next level of inspections with Rogue's Phased Array UT expertise.

How We Add Value:

Strategic Consulting:

Collaborate with our PA experts for strategic consulting, ensuring your inspections align with industry best practices and standards.

Tailored PA Procedures:

Unlock the full potential of PAUT inspections with procedures customized to your specific applications. Our detailed protocols optimize the detection and characterization of defects.

Comprehensive Training Programs:

Invest in your team's proficiency with our PAUT training programs. From basic principles to advanced techniques, we equip your personnel with the knowledge needed for successful PA inspections.

Innovative Solutions for Complex Inspections:

Tackle complex inspections confidently with our innovative PA solutions. We provide tools and technologies that enhance your ability to address challenging scenarios and achieve reliable results.

-

![FMC/FTM]()

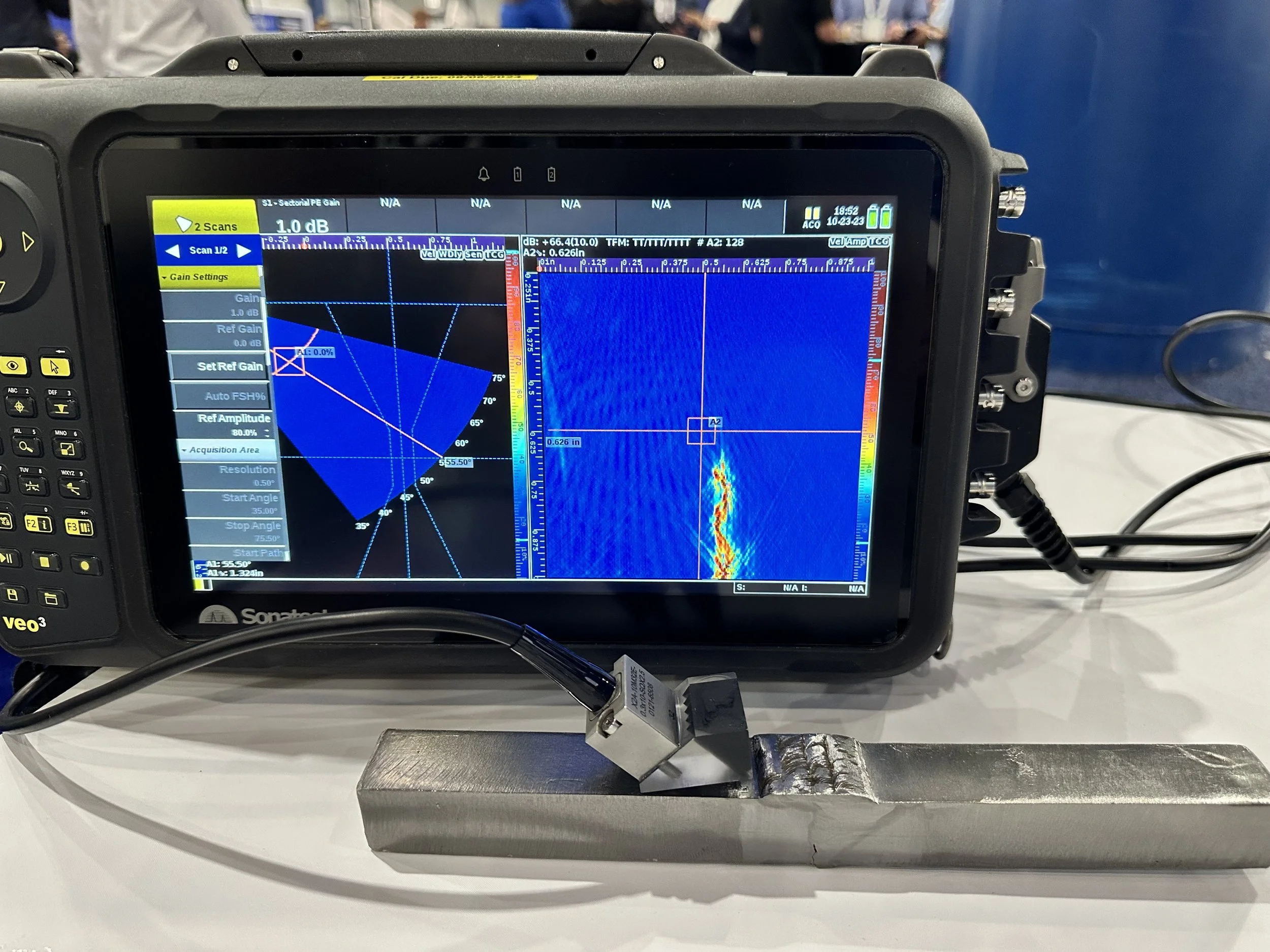

Full Matrix Capture/Total Focusing Method (FMC/TFM)

Precision in FMC/TFM Inspections:

Experience precision like never before with Rogue NDT's expertise in Full Matrix Capture (FMC) and Total Focusing Method (TFM).

How We Add Value:

Strategic Consulting for FMC/TFM Integration:

Collaborate with our consultants to seamlessly integrate FMC/TFM into your inspections. We provide guidance on optimal implementation strategies.

Customized Procedures for Maximum Depth:

Maximize the depth of your inspections with FMC/TFM procedures tailored to your specific applications. Our protocols ensure unparalleled defect characterization.

Advanced Training for FMC/TFM Mastery:

Propel your team to mastery with our advanced training in FMC/TFM. We cover the intricacies of these techniques, empowering your personnel to excel in challenging inspection scenarios.

Cutting-Edge Solutions for High-Performance Materials:

Stay ahead in inspections involving high-performance materials with our cutting-edge FMC/TFM solutions. We provide tools and technologies designed to meet the demands of the most critical inspections.

-

![Time of Flight Diffraction (TOFD)]()

Automated Ultrasonic Testing (AUT)

DescriptionExplore the forefront of inspection technology with Rogue NDT's expertise in Automated Ultrasonic Testing (AUT). Tailored for weld inspections, our AUT services encompass Conventional UT, Phased Array (PA), and Total Focusing Method (TFM) technologies. We navigate the intricacies of weld examinations, ensuring the highest precision and reliability. Whether you're in the aerospace, oil and gas, or other sectors, our AUT solutions redefine industry standards, providing cutting-edge tools and methodologies for flawless inspections. goes here

-

![Visual Weld Inspection]()

Visual Testing (VT)

Embark on a journey of visual excellence with Rogue's Visual Testing (VT) services.

Our strategic consulting in VT enhances your inspection processes, ensuring a comprehensive approach to detect surface irregularities, weld defects, and other visual imperfections.

Customized VT procedures cater to the specific demands of your applications, providing detailed protocols for accurate assessments.

Elevate your team's proficiency with our VT training programs, equipping personnel with the skills for meticulous visual inspections.

Our innovative VT solutions integrate cutting-edge technologies, enhancing the clarity and depth of visual examinations for a thorough and reliable assessment.es here

-

![Magnetic Particle Testing (MT)]()

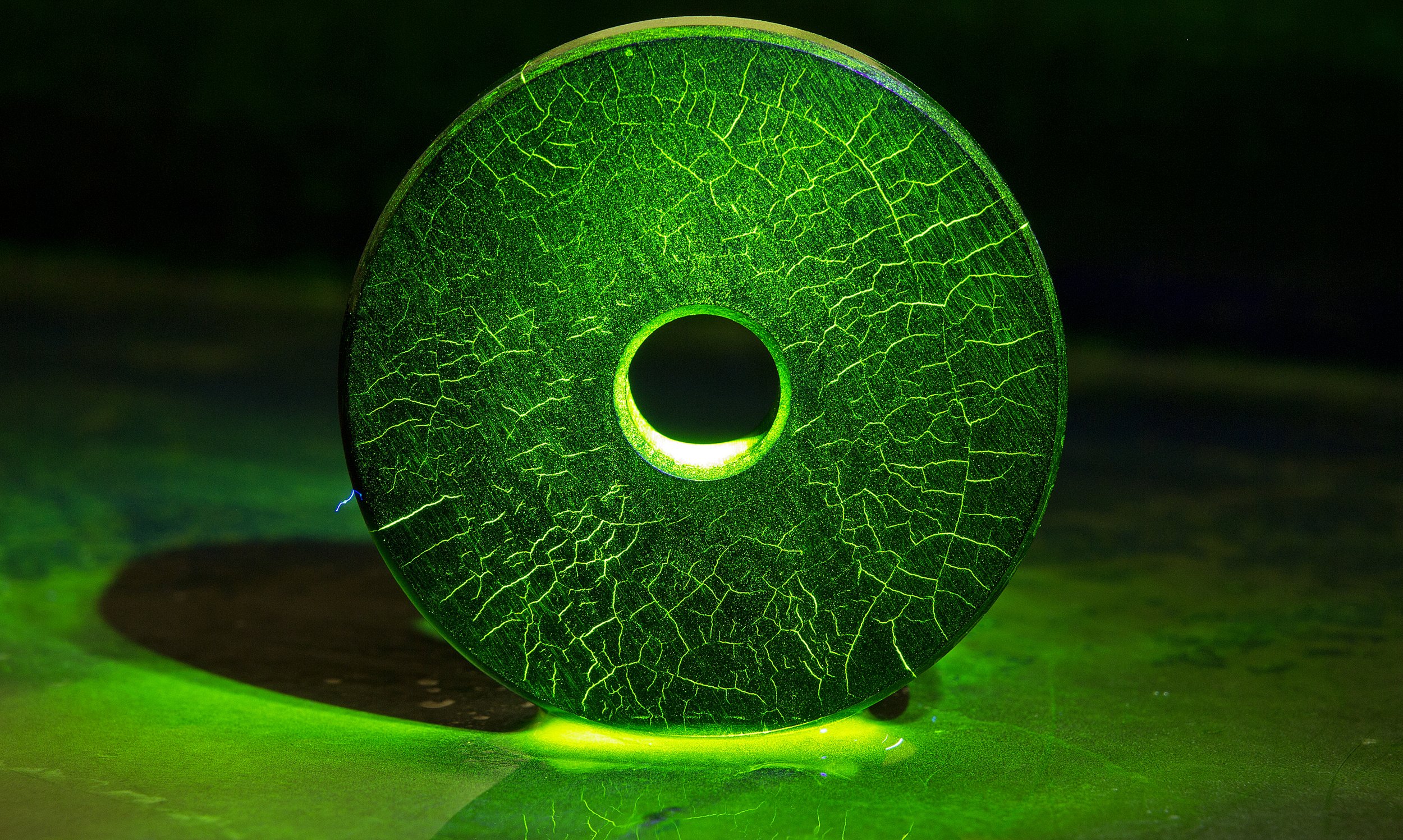

Magnetic Particle Testing (MT)

At Rogue, Magnetic Particle Testing (MT) becomes a precision art.

Our strategic consulting in MT ensures the strategic application of magnetic particles to detect surface and near-surface flaws in ferromagnetic materials.

Tailored MT procedures optimize the detection of defects, providing detailed protocols that enhance the reliability of inspections.

Invest in the proficiency of your team through our MT training programs, covering fundamental principles and advanced techniques.

Rely on our innovative MT solutions, incorporating the latest advancements to achieve exceptional flaw detection and characterization, setting new standards for reliability in magnetic particle inspections.

-

![Liquid Dye Penetrant Testing]()

Penetrant Testing (PT)

Unlock the potential of flaw identification with Rogue's Penetrant Testing (PT) services.

Our strategic consulting in PT maximizes the effectiveness of penetrant materials to detect surface flaws in non-porous materials.

Customized PT procedures cater to your specific applications, offering detailed protocols that ensure a thorough assessment of flaws.

Elevate your team's skills through our PT training programs, providing comprehensive knowledge from basic principles to advanced techniques.

Our innovative PT solutions leverage cutting-edge materials and methods, enhancing the sensitivity and accuracy of flaw detection for a meticulous and reliable inspection process.